| Payment & Shipping Terms | Supply Capacity |

|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU | Production Capacity: | 50-100 each month |

| Min. Order: | 5 Piece/Pieces | Packing: | carton |

| Means of Transport: | Ocean, Air, Land | Delivery Date: | as per the... |

Model:

Introduction:

Profile

Single seal/Unbalanced/Dependent on direction of rotation

Seal series is mainly used in chemical pumps, sewage pumps , industrial pumps , ect . For normal corrosive medium. Its rotaing seal uses pin or holding screw to achieve reliable drive. Its axial size is small and has a high interchangeability. It is suitable for viscous medium.

Operating limits

Specification: 20~65mm

Pressure: ≤1.2Mpa

Temperature:- -20~180℃

Linear speed:≤15m/s

Axial movement:±0.5mm

Combination of materials

Sealing face : Gradphite,Silicon carbide, Tungsten carbide, Aluminun oxide

Secondary sealing:Acrylonitrile rubber, Fluorine rubber, Ethylene propylene rubber, PTFE

Metal component : Stainless steel

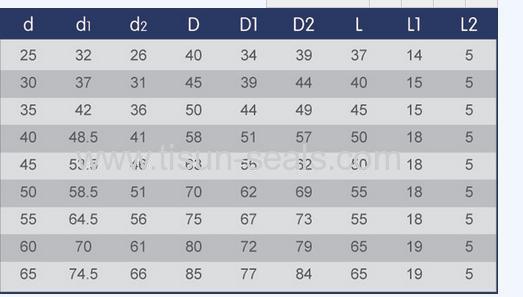

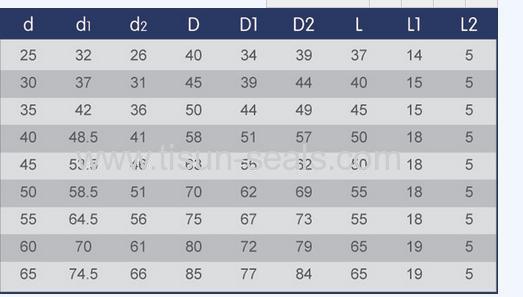

unit:mm

unit:mm

Seal operation notice:

1: after pump start-up if there is a slight leakage phenomenon, should be observed for a period of time.Such as 4 hours of continuous running, still don't reduce the leakage, should stop the pump to check.

2: the operating pressure of the pump should be smooth, pressure fluctuation is not more than 1 kg/cm2.

3: the pump in operation, should avoid to occur, in order to avoid damage in seal face dry friction and sealing.

4: sealing condition check regularly.In operation, when the leak than standard, heavy oil is not more than 5 drops per minute, light oil is not more than 10 / points, such as 2-3 days still no improvement, you should stop the pump to check the sealing device.

Category: PTFE Mechanical seals

Related Category: Cartridge mechanical seals

Pump shaft seals

Water pump seals

Industrial pump seals

Air compressor mechanical seals

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)